Tool box pre start talk pdf

Health and safety talks are easier to start when you have something prepared, so get some notes together on a relevant subject, or use one of our pre-prepared toolbox talks. This article was written by Emma at HASpod .

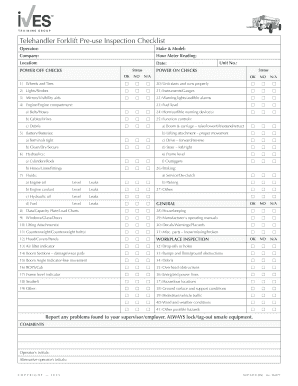

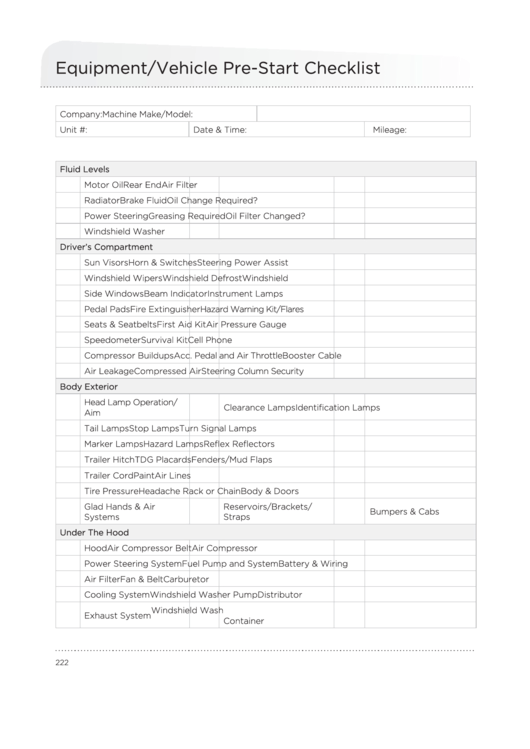

Equipment Pre Start Checklist. A Equipment Pre Start Checklist helps you to assess the serviceability of your equipment before you use it. They will assist to uncover potential hazards or flaws due to misuse, wear and tear or poor maintenance.

The term “Toolbox Talk” was originally used as a way to encourage building workers to have a regular documented safety meeting. The best time to do this was considered to be when they stood around the tool box in the morning before starting work, so the term Toolbox Talk was born.

CASSA Compliant Automated Safety Systems Australia OHSE MANAGEMENT PLAN DATE: _15/01_/2011_ VERSION NO: _2__ 001 – Toolbox/pre-start talks

When ‘Hearts and Minds’ are not ‘Hearts and Minds’One of the profound findings of current neurophysiological and neuropsychological research is that the human person is an embodied mind, not a behaviourist computer on top of a body.Research by:Damasio – The Feeling of What Happens; Descartes ErrorVarela – The Embodied MindClaxton

Pre-shift inspections provide an opportunity to observe and report maintenance and safety concerns for any equipment. Be Prepared – Read and know the operator’s manual for specific equipment. – Understand the importance of completing pre-shift inspection. – Stress to fellow employees the importance of pre-shift inspection. Inspect Carefully – Inspect the ENTIRE piece of equipment

out by the operator as soon as practicable at the start of the shift (or when the vehicle is put to work for the first time that shift). Recording Vehicle Daily Safety Checks Each vehicle must have its own Vehicle Daily Safety Check Book. The book should be kept in the vehicle cab so it can be filled in immediately after the daily checks have been done. Tarmac has two books for recording daily

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

Tool Box Talk Scenarios 2 and 6 Working on Fixed Plant/Conveyors Introduction Cleaning or adjusting machinery while it is running and the unexpected start up of equipment has caused

Our “toolbox talks packs” fact sheets are ready to go: short and succinct, covering over 100 topics in the electrotechnology industry. They are suitable for many different subjects and will help you get your safety message across to your workers.

084: Tools – Hand Tool Safety Why this is important A misapplied hand tool can easily result in injury. A worn or damaged tool can easily result in injury.

Toolbox Safety Talk Personal Protective Equipment (PPE) Environmental Health & S afety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210

Inspect construction sites, restaurants inspections for food safety, conduct temperature checks, pre-flight checks, toolbox talks and more. It is the mobile forms inspection solution for all industries.

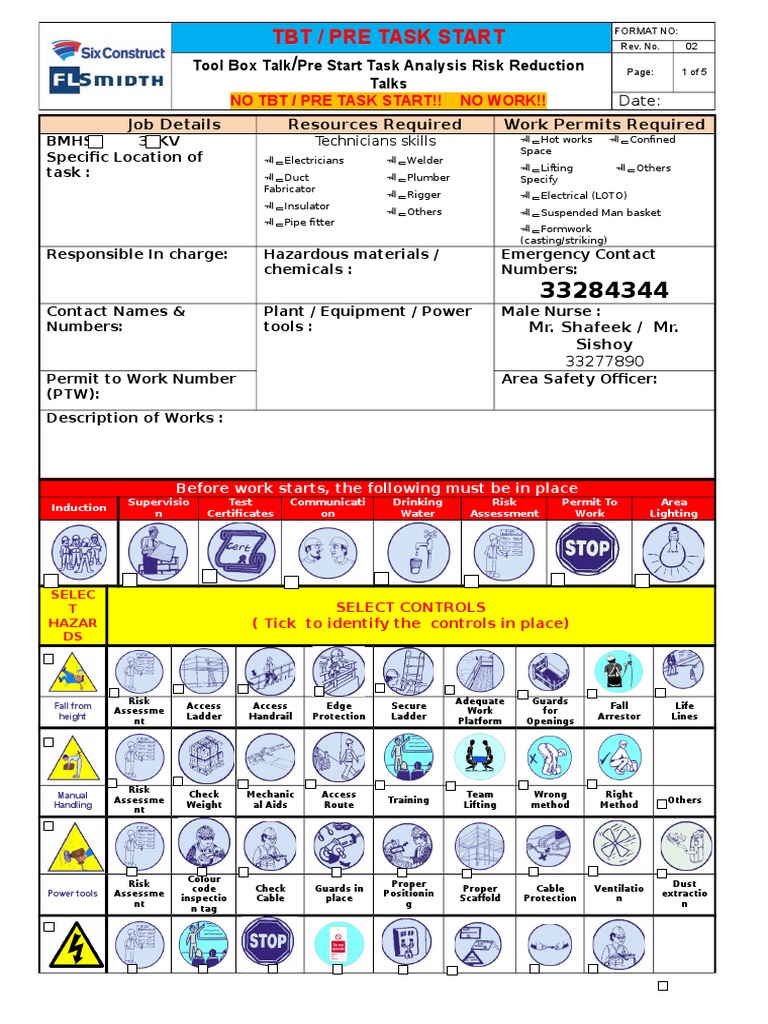

View, download and print Toolbox Safety Meetings/pre-start Talks pdf template or form online. 6 Safety Meeting Templates are collected for any of your needs.

Toolbox Talks are intended to facilitate health and safety

70 Workplace Safety Talks « Safety Awakenings

The pre-start meeting is used as a tool to alert workers to these new training requirements and keep track of who has and has not completed it. Drug and Alcohol Screening While drug and alcohol screening routines are different on every site, the pre-start meeting is often one of the times at which random drug and alcohol testing is regularly conducted.

Tool Box Talks. Various types of Tool Box Talk documentation can be found down the left side of this page. A toolbox talk is a short safety talk, normally delivered on site (not in a training room) and on a specific subject matter.

Tool Box Talk No 1 MANUAL HANDLING Page 1 of 1 Manual Handling Overview This talk will cover: considerations and good techniques for manual handling.

Tool Box Talk Plant Checks GAP Tool Box Talk: Plant Checks To provide guidance on: The precautions to be taken when working with Plant and Equipment Pre-use checks prior to work starting Regulations The Management of Health & Safety at Work Regulations 1999 Supply of Machinery (Safety) Regulations 2008 Provision and Use of Work Equipment Regulations 1998 Personal …

Download these safety talks, print them up, and use them in your pre-shift, workplace, employee safety meetings (aka tool box talks or tailgate talks). You also might want to use them in – monthly department safety meetings, and your new hire safety orientation training program.

TOOL BOX TALK Vehicle Safety Inspections Introduction: The condition of your vehicle is a safety factor that you, the driver, can control. You decide when the maintenance is done and at what intervals. But what are the risks when vehicle maintenance is neglected? One risk is the inability to maintain control? Another risk is a break down on the side of the highway? Budget money for regular

These are also referred to as; toolbox talks, (daily) site inductions, or line-side briefings. It doesn’t matter what you call them they are generally a good idea.

Free Toolbox Talks Download This package contains 70 toolbox talk documents covering a wide variety of health and safety issues in the workplace. All are in MS Word 97-2003 format and can be fully edited to include things like your company logo if required.

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

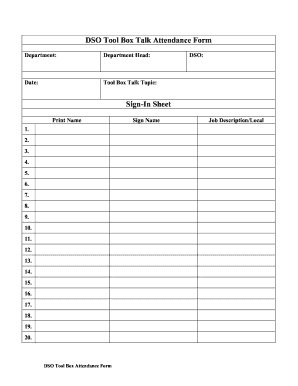

Source: OHSE Subbypack, OSHE14 – Toolbox/ pre-start talks A10611150 Toolbox safety meetings/pre-start talks Ref: Version: All Toolbox safety meetings/pre-start talks undertaken on behalf of are recorded on this form

MR 003 Toolbox Pre-Start Talks For Advice On Your Workwear & Safety Order, Call Now

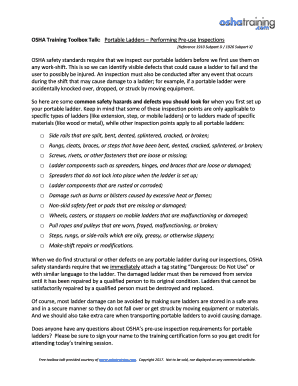

Pre Use Safety Checks. Clean the outside of the machine. Make sure the harness is not damaged. Clean the air filter. Replace if necessary; Make sure the throttle trigger lock and the throttle function correctly from a safety point.

Toolbox Safety Talk Hand and Power Tools Environmental Health & Safety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210 Ithaca, NY 14850

Toolbox talks are a way to ensure all workers are participating in safety activities, and have an opportunity to discuss hazards/controls, incidents and accidents.

Pre-Task Planning Toolbox Talking Points by SE Region Safety Team 05/04/2015 Pre-task plans are required on all of Barton Malow projects.

The person conducting the talk can use these questions to start a discussion that will make the information relevant to participating employees. Learn more. Links to additional resources are given for each Toolbox Talk. The links are provided to direct safety professionals and workers to publicly available information that can be used to learn more about the topic or modified to create

When you design your own specialized tool box talks, remember some basic principals in giving instruction: Introduce what you are going to explain them, the …

Toolbox Talk #10 HAND & POWER TOOLS

Use the proper tool for the job Follow the manufacturer’s instructions If unsure about use, ask a supervisor or coworker for clarification

Pre-start checklists are essential to ensure that employees and contractors assess all aspects of the equipment and workplace environment and greatly reduce accidents on work sites. Prior to operating the machine, the driver completes a visual assessment, check levels, wear, indicator lights, or signs of …

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to – witcher 3 how to make druid talk Toolbox/Pre-start talks Toolbox/Pre-start talks_0313 Contractor name Contractor ID Project name Duration Toolbox/Pre-start talks are recorded on this form and signed by participants.

Toolbox or Pre-Start Talks are commonly used as a means of conducting and documenting the important information and training provided to workers. As the document is signed by the workers it provides proof of their attendance. If you require topics and information for discussion at your toolbox talks then you may benefi

Daily Toolbox Meeting Form End-of Day Review: Were there any Incidents, Injuries or First-Aid Reports for the day?: Yes No Describe:

and Operational Works Decision Notices, including all pre-start requirements and any imposed conditions from Concurrence agencies. This document is in three parts and should be attached to any supporting documentation.

Tool Box Talk Issue: 1.0 Manual Handling Author: SHEQ Coordinator Approver: SHEQ Manager Approval Date: 19/03/12 Manual Handling Introduction In the UK, 54 million working days are lost each year because of pain, strain and injuries to the back. Back strains are a common injury too. These can be caused by using poor techniques to move materials such as twisting and turning while lifting

With SiteDocs you can upload pre-written safety talks to your account and have your workers instantly access them on their iphone/android or tablet. Once they have read the toolbox talk, workers will be able to select their name and sign the form right on the device. Rest assured, every worker that is part of the safety meeting will be able to sign off on the same form.

CONTRACTORS PRE-START SAFETY CHECKLIST CONTRACTORS Pre-start SAFETY Checklist Published: February 2012 Version 1.0 Authorised by UWA …

Site briefing/toolbox meeting minutes Project information Who is running this meeting? Agenda items Health and safety issues This document is a companion document to the site inspection checklist. Site name Name Agenda items Theme of the week (topic for focus) Company Date Office location Date: Company Is this a site-specific or in-house meeting? Site Name After start Frequently used Site

Toolbox Talk Machine Safety – Before Operations Pre-Start Procedures Read and understand the Operation and Maintenance Manual Always perform a pre-shift walk around inspection

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

All Toolbox / Pre-start Talks undertaken on behalf of [Insert Company Name] are recorded on this form and signed by participants. All corrective actions noted on this form are implemented and signed by the nominated person.

Date Company Site Name After start Frequently used Site

How To Start A Safety Talk HASpod

Tool box talk templates for Toolbox Procedures Toolbox

Toolbox Talk Machine Safety Before Operations Pre-Start

084 Tools – Hand Tool Safety NECA

Toolbox Talks CPWR

Equipment Pre Start Checklist Books Pertrain Pty Limited

A-Z of Safety Toolbox Topics Toolbox Talks T NECA

– Manual Handling Tool Box talk Health & Safety Hub

TOOLBOX PRE-START TALKS businesssavvy.com.au

TOOL BOX TALKS A YEAR’S WORTH OF WEEKLY SAFETY

Toolbox talks / pre-start meetings Site Safe

Toolbox Pre-Start Talks NECA Safety Specialists

Toolbox talks / pre-start meetings Site Safe

Tool Box Talk No 1 MANUAL HANDLING Page 1 of 1 Manual Handling Overview This talk will cover: considerations and good techniques for manual handling.

Equipment Pre Start Checklist. A Equipment Pre Start Checklist helps you to assess the serviceability of your equipment before you use it. They will assist to uncover potential hazards or flaws due to misuse, wear and tear or poor maintenance.

Tool Box Talk Plant Checks GAP Tool Box Talk: Plant Checks To provide guidance on: The precautions to be taken when working with Plant and Equipment Pre-use checks prior to work starting Regulations The Management of Health & Safety at Work Regulations 1999 Supply of Machinery (Safety) Regulations 2008 Provision and Use of Work Equipment Regulations 1998 Personal …

out by the operator as soon as practicable at the start of the shift (or when the vehicle is put to work for the first time that shift). Recording Vehicle Daily Safety Checks Each vehicle must have its own Vehicle Daily Safety Check Book. The book should be kept in the vehicle cab so it can be filled in immediately after the daily checks have been done. Tarmac has two books for recording daily

Toolbox talks are a way to ensure all workers are participating in safety activities, and have an opportunity to discuss hazards/controls, incidents and accidents.

SafetyRisk.net Humanising Safety and Embracing Real Risk

Toolbox or Pre-Start Talks Form – Occupational Safety

TOOL BOX TALK Vehicle Safety Inspections Introduction: The condition of your vehicle is a safety factor that you, the driver, can control. You decide when the maintenance is done and at what intervals. But what are the risks when vehicle maintenance is neglected? One risk is the inability to maintain control? Another risk is a break down on the side of the highway? Budget money for regular

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

Free Toolbox Talks Download This package contains 70 toolbox talk documents covering a wide variety of health and safety issues in the workplace. All are in MS Word 97-2003 format and can be fully edited to include things like your company logo if required.

Pre-Task Planning Toolbox Talking Points by SE Region Safety Team 05/04/2015 Pre-task plans are required on all of Barton Malow projects.

Download these safety talks, print them up, and use them in your pre-shift, workplace, employee safety meetings (aka tool box talks or tailgate talks). You also might want to use them in – monthly department safety meetings, and your new hire safety orientation training program.

Pre Use Safety Checks. Clean the outside of the machine. Make sure the harness is not damaged. Clean the air filter. Replace if necessary; Make sure the throttle trigger lock and the throttle function correctly from a safety point.

084: Tools – Hand Tool Safety Why this is important A misapplied hand tool can easily result in injury. A worn or damaged tool can easily result in injury.

All Toolbox / Pre-start Talks undertaken on behalf of [Insert Company Name] are recorded on this form and signed by participants. All corrective actions noted on this form are implemented and signed by the nominated person.

Tool Box Talk Plant Checks GAP Tool Box Talk: Plant Checks To provide guidance on: The precautions to be taken when working with Plant and Equipment Pre-use checks prior to work starting Regulations The Management of Health & Safety at Work Regulations 1999 Supply of Machinery (Safety) Regulations 2008 Provision and Use of Work Equipment Regulations 1998 Personal …

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

When ‘Hearts and Minds’ are not ‘Hearts and Minds’One of the profound findings of current neurophysiological and neuropsychological research is that the human person is an embodied mind, not a behaviourist computer on top of a body.Research by:Damasio – The Feeling of What Happens; Descartes ErrorVarela – The Embodied MindClaxton

When you design your own specialized tool box talks, remember some basic principals in giving instruction: Introduce what you are going to explain them, the …

Toolbox talks / pre-start meetings Site Safe

TOOLBOX PRE-START TALKS businesssavvy.com.au

Pre-shift inspections provide an opportunity to observe and report maintenance and safety concerns for any equipment. Be Prepared – Read and know the operator’s manual for specific equipment. – Understand the importance of completing pre-shift inspection. – Stress to fellow employees the importance of pre-shift inspection. Inspect Carefully – Inspect the ENTIRE piece of equipment

MR 003 Toolbox Pre-Start Talks For Advice On Your Workwear & Safety Order, Call Now

When you design your own specialized tool box talks, remember some basic principals in giving instruction: Introduce what you are going to explain them, the …

Daily Toolbox Meeting Form End-of Day Review: Were there any Incidents, Injuries or First-Aid Reports for the day?: Yes No Describe:

CASSA Compliant Automated Safety Systems Australia OHSE MANAGEMENT PLAN DATE: _15/01_/2011_ VERSION NO: _2__ 001 – Toolbox/pre-start talks

The term “Toolbox Talk” was originally used as a way to encourage building workers to have a regular documented safety meeting. The best time to do this was considered to be when they stood around the tool box in the morning before starting work, so the term Toolbox Talk was born.

Toolbox or Pre-Start Talks are commonly used as a means of conducting and documenting the important information and training provided to workers. As the document is signed by the workers it provides proof of their attendance. If you require topics and information for discussion at your toolbox talks then you may benefi

Use the proper tool for the job Follow the manufacturer’s instructions If unsure about use, ask a supervisor or coworker for clarification

and Operational Works Decision Notices, including all pre-start requirements and any imposed conditions from Concurrence agencies. This document is in three parts and should be attached to any supporting documentation.

Pre-Task Planning Toolbox Talking Points by SE Region Safety Team 05/04/2015 Pre-task plans are required on all of Barton Malow projects.

Equipment Pre Start Checklist. A Equipment Pre Start Checklist helps you to assess the serviceability of your equipment before you use it. They will assist to uncover potential hazards or flaws due to misuse, wear and tear or poor maintenance.

View, download and print Toolbox Safety Meetings/pre-start Talks pdf template or form online. 6 Safety Meeting Templates are collected for any of your needs.

Tool Box Talk Issue: 1.0 Manual Handling Author: SHEQ Coordinator Approver: SHEQ Manager Approval Date: 19/03/12 Manual Handling Introduction In the UK, 54 million working days are lost each year because of pain, strain and injuries to the back. Back strains are a common injury too. These can be caused by using poor techniques to move materials such as twisting and turning while lifting

Toolbox/Pre-start talks Toolbox/Pre-start talks_0313 Contractor name Contractor ID Project name Duration Toolbox/Pre-start talks are recorded on this form and signed by participants.

Toolbox Talks are intended to facilitate health and safety

Toolbox Talk #10 HAND & POWER TOOLS

Toolbox Safety Talk Hand and Power Tools Environmental Health & Safety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210 Ithaca, NY 14850

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

Use the proper tool for the job Follow the manufacturer’s instructions If unsure about use, ask a supervisor or coworker for clarification

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

Pre-start checklists are essential to ensure that employees and contractors assess all aspects of the equipment and workplace environment and greatly reduce accidents on work sites. Prior to operating the machine, the driver completes a visual assessment, check levels, wear, indicator lights, or signs of …

When ‘Hearts and Minds’ are not ‘Hearts and Minds’One of the profound findings of current neurophysiological and neuropsychological research is that the human person is an embodied mind, not a behaviourist computer on top of a body.Research by:Damasio – The Feeling of What Happens; Descartes ErrorVarela – The Embodied MindClaxton

Tool Box Talk No 1 MANUAL HANDLING Page 1 of 1 Manual Handling Overview This talk will cover: considerations and good techniques for manual handling.

Tool Box Talk Scenarios 2 and 6 Working on Fixed Plant/Conveyors Introduction Cleaning or adjusting machinery while it is running and the unexpected start up of equipment has caused

Site briefing/toolbox meeting minutes Project information Who is running this meeting? Agenda items Health and safety issues This document is a companion document to the site inspection checklist. Site name Name Agenda items Theme of the week (topic for focus) Company Date Office location Date: Company Is this a site-specific or in-house meeting? Site Name After start Frequently used Site

The person conducting the talk can use these questions to start a discussion that will make the information relevant to participating employees. Learn more. Links to additional resources are given for each Toolbox Talk. The links are provided to direct safety professionals and workers to publicly available information that can be used to learn more about the topic or modified to create

Inspect construction sites, restaurants inspections for food safety, conduct temperature checks, pre-flight checks, toolbox talks and more. It is the mobile forms inspection solution for all industries.

SafetyRisk.net Humanising Safety and Embracing Real Risk

Points raised/comments Corrective action Action by Action

The term “Toolbox Talk” was originally used as a way to encourage building workers to have a regular documented safety meeting. The best time to do this was considered to be when they stood around the tool box in the morning before starting work, so the term Toolbox Talk was born.

Toolbox/Pre-start talks Toolbox/Pre-start talks_0313 Contractor name Contractor ID Project name Duration Toolbox/Pre-start talks are recorded on this form and signed by participants.

When ‘Hearts and Minds’ are not ‘Hearts and Minds’One of the profound findings of current neurophysiological and neuropsychological research is that the human person is an embodied mind, not a behaviourist computer on top of a body.Research by:Damasio – The Feeling of What Happens; Descartes ErrorVarela – The Embodied MindClaxton

Site briefing/toolbox meeting minutes Project information Who is running this meeting? Agenda items Health and safety issues This document is a companion document to the site inspection checklist. Site name Name Agenda items Theme of the week (topic for focus) Company Date Office location Date: Company Is this a site-specific or in-house meeting? Site Name After start Frequently used Site

Inspect construction sites, restaurants inspections for food safety, conduct temperature checks, pre-flight checks, toolbox talks and more. It is the mobile forms inspection solution for all industries.

Toolbox Safety Talk Hand and Power Tools Environmental Health & Safety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210 Ithaca, NY 14850

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

Free Toolbox Talks Download This package contains 70 toolbox talk documents covering a wide variety of health and safety issues in the workplace. All are in MS Word 97-2003 format and can be fully edited to include things like your company logo if required.

All Toolbox / Pre-start Talks undertaken on behalf of [Insert Company Name] are recorded on this form and signed by participants. All corrective actions noted on this form are implemented and signed by the nominated person.

Our “toolbox talks packs” fact sheets are ready to go: short and succinct, covering over 100 topics in the electrotechnology industry. They are suitable for many different subjects and will help you get your safety message across to your workers.

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

Toolbox Talking Points Barton Malow Company

Tool box talk templates for Toolbox Procedures Toolbox

Toolbox Talk Machine Safety – Before Operations Pre-Start Procedures Read and understand the Operation and Maintenance Manual Always perform a pre-shift walk around inspection

Use the proper tool for the job Follow the manufacturer’s instructions If unsure about use, ask a supervisor or coworker for clarification

With SiteDocs you can upload pre-written safety talks to your account and have your workers instantly access them on their iphone/android or tablet. Once they have read the toolbox talk, workers will be able to select their name and sign the form right on the device. Rest assured, every worker that is part of the safety meeting will be able to sign off on the same form.

All Toolbox / Pre-start Talks undertaken on behalf of [Insert Company Name] are recorded on this form and signed by participants. All corrective actions noted on this form are implemented and signed by the nominated person.

Tool Box Talks. Various types of Tool Box Talk documentation can be found down the left side of this page. A toolbox talk is a short safety talk, normally delivered on site (not in a training room) and on a specific subject matter.

When you design your own specialized tool box talks, remember some basic principals in giving instruction: Introduce what you are going to explain them, the …

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

out by the operator as soon as practicable at the start of the shift (or when the vehicle is put to work for the first time that shift). Recording Vehicle Daily Safety Checks Each vehicle must have its own Vehicle Daily Safety Check Book. The book should be kept in the vehicle cab so it can be filled in immediately after the daily checks have been done. Tarmac has two books for recording daily

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

Toolbox or Pre-Start Talks are commonly used as a means of conducting and documenting the important information and training provided to workers. As the document is signed by the workers it provides proof of their attendance. If you require topics and information for discussion at your toolbox talks then you may benefi

Toolbox Safety Talk Personal Protective Equipment (PPE) Environmental Health & S afety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

Toolbox Safety Talk Hand and Power Tools Environmental Health & Safety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210 Ithaca, NY 14850

Tool Box Talk Plant Checks GAP Tool Box Talk: Plant Checks To provide guidance on: The precautions to be taken when working with Plant and Equipment Pre-use checks prior to work starting Regulations The Management of Health & Safety at Work Regulations 1999 Supply of Machinery (Safety) Regulations 2008 Provision and Use of Work Equipment Regulations 1998 Personal …

Toolbox talks / pre-start meetings Site Safe

Pre-Start Checklists Lockbox Safety Documentation

These are also referred to as; toolbox talks, (daily) site inductions, or line-side briefings. It doesn’t matter what you call them they are generally a good idea.

Pre-shift inspections provide an opportunity to observe and report maintenance and safety concerns for any equipment. Be Prepared – Read and know the operator’s manual for specific equipment. – Understand the importance of completing pre-shift inspection. – Stress to fellow employees the importance of pre-shift inspection. Inspect Carefully – Inspect the ENTIRE piece of equipment

The pre-start meeting is used as a tool to alert workers to these new training requirements and keep track of who has and has not completed it. Drug and Alcohol Screening While drug and alcohol screening routines are different on every site, the pre-start meeting is often one of the times at which random drug and alcohol testing is regularly conducted.

Pre-Task Planning Toolbox Talking Points by SE Region Safety Team 05/04/2015 Pre-task plans are required on all of Barton Malow projects.

Toolbox Safety Talk Hand and Power Tools Environmental Health & Safety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210 Ithaca, NY 14850

When ‘Hearts and Minds’ are not ‘Hearts and Minds’One of the profound findings of current neurophysiological and neuropsychological research is that the human person is an embodied mind, not a behaviourist computer on top of a body.Research by:Damasio – The Feeling of What Happens; Descartes ErrorVarela – The Embodied MindClaxton

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

Tool Box Talk Plant Checks GAP Tool Box Talk: Plant Checks To provide guidance on: The precautions to be taken when working with Plant and Equipment Pre-use checks prior to work starting Regulations The Management of Health & Safety at Work Regulations 1999 Supply of Machinery (Safety) Regulations 2008 Provision and Use of Work Equipment Regulations 1998 Personal …

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

Tool Box Talk Issue: 1.0 Manual Handling Author: SHEQ Coordinator Approver: SHEQ Manager Approval Date: 19/03/12 Manual Handling Introduction In the UK, 54 million working days are lost each year because of pain, strain and injuries to the back. Back strains are a common injury too. These can be caused by using poor techniques to move materials such as twisting and turning while lifting

Inspect construction sites, restaurants inspections for food safety, conduct temperature checks, pre-flight checks, toolbox talks and more. It is the mobile forms inspection solution for all industries.

MR 003 Toolbox Pre-Start Talks For Advice On Your Workwear & Safety Order, Call Now

Toolbox Talk #10 HAND & POWER TOOLS

70 Workplace Safety Talks « Safety Awakenings

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

Tool Box Talk Scenarios 2 and 6 Working on Fixed Plant/Conveyors Introduction Cleaning or adjusting machinery while it is running and the unexpected start up of equipment has caused

The pre-start meeting is used as a tool to alert workers to these new training requirements and keep track of who has and has not completed it. Drug and Alcohol Screening While drug and alcohol screening routines are different on every site, the pre-start meeting is often one of the times at which random drug and alcohol testing is regularly conducted.

MR 003 Toolbox Pre-Start Talks For Advice On Your Workwear & Safety Order, Call Now

When ‘Hearts and Minds’ are not ‘Hearts and Minds’One of the profound findings of current neurophysiological and neuropsychological research is that the human person is an embodied mind, not a behaviourist computer on top of a body.Research by:Damasio – The Feeling of What Happens; Descartes ErrorVarela – The Embodied MindClaxton

The term “Toolbox Talk” was originally used as a way to encourage building workers to have a regular documented safety meeting. The best time to do this was considered to be when they stood around the tool box in the morning before starting work, so the term Toolbox Talk was born.

These are also referred to as; toolbox talks, (daily) site inductions, or line-side briefings. It doesn’t matter what you call them they are generally a good idea.

CASSA Compliant Automated Safety Systems Australia OHSE MANAGEMENT PLAN DATE: _15/01_/2011_ VERSION NO: _2__ 001 – Toolbox/pre-start talks

Pre-shift inspections provide an opportunity to observe and report maintenance and safety concerns for any equipment. Be Prepared – Read and know the operator’s manual for specific equipment. – Understand the importance of completing pre-shift inspection. – Stress to fellow employees the importance of pre-shift inspection. Inspect Carefully – Inspect the ENTIRE piece of equipment

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

Toolbox Safety Talk Hand and Power Tools Environmental Health & Safety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210 Ithaca, NY 14850

084 Tools – Hand Tool Safety NECA

CONTRACTORS PRE-START SAFETY CHECKLIST

The pre-start meeting is used as a tool to alert workers to these new training requirements and keep track of who has and has not completed it. Drug and Alcohol Screening While drug and alcohol screening routines are different on every site, the pre-start meeting is often one of the times at which random drug and alcohol testing is regularly conducted.

With SiteDocs you can upload pre-written safety talks to your account and have your workers instantly access them on their iphone/android or tablet. Once they have read the toolbox talk, workers will be able to select their name and sign the form right on the device. Rest assured, every worker that is part of the safety meeting will be able to sign off on the same form.

and Operational Works Decision Notices, including all pre-start requirements and any imposed conditions from Concurrence agencies. This document is in three parts and should be attached to any supporting documentation.

Health and safety talks are easier to start when you have something prepared, so get some notes together on a relevant subject, or use one of our pre-prepared toolbox talks. This article was written by Emma at HASpod .

out by the operator as soon as practicable at the start of the shift (or when the vehicle is put to work for the first time that shift). Recording Vehicle Daily Safety Checks Each vehicle must have its own Vehicle Daily Safety Check Book. The book should be kept in the vehicle cab so it can be filled in immediately after the daily checks have been done. Tarmac has two books for recording daily

CASSA Compliant Automated Safety Systems Australia OHSE MANAGEMENT PLAN DATE: _15/01_/2011_ VERSION NO: _2__ 001 – Toolbox/pre-start talks

The term “Toolbox Talk” was originally used as a way to encourage building workers to have a regular documented safety meeting. The best time to do this was considered to be when they stood around the tool box in the morning before starting work, so the term Toolbox Talk was born.

The person conducting the talk can use these questions to start a discussion that will make the information relevant to participating employees. Learn more. Links to additional resources are given for each Toolbox Talk. The links are provided to direct safety professionals and workers to publicly available information that can be used to learn more about the topic or modified to create

Free Toolbox Talks Download This package contains 70 toolbox talk documents covering a wide variety of health and safety issues in the workplace. All are in MS Word 97-2003 format and can be fully edited to include things like your company logo if required.

Tool Box Talk Scenarios 2 and 6 Working on Fixed Plant/Conveyors Introduction Cleaning or adjusting machinery while it is running and the unexpected start up of equipment has caused

Tool Box Talk No 1 MANUAL HANDLING Page 1 of 1 Manual Handling Overview This talk will cover: considerations and good techniques for manual handling.

Download these safety talks, print them up, and use them in your pre-shift, workplace, employee safety meetings (aka tool box talks or tailgate talks). You also might want to use them in – monthly department safety meetings, and your new hire safety orientation training program.

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

Toolbox Safety Talk Personal Protective Equipment (PPE) Environmental Health & S afety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210

Toolbox Safety Meetings/pre-Start Talks (Page 2 of 2) in pdf

Manual Handling Tool Box talk Health & Safety Hub

Toolbox/Pre-start talks Toolbox/Pre-start talks_0313 Contractor name Contractor ID Project name Duration Toolbox/Pre-start talks are recorded on this form and signed by participants.

and Operational Works Decision Notices, including all pre-start requirements and any imposed conditions from Concurrence agencies. This document is in three parts and should be attached to any supporting documentation.

Tool Box Talk Issue: 1.0 Manual Handling Author: SHEQ Coordinator Approver: SHEQ Manager Approval Date: 19/03/12 Manual Handling Introduction In the UK, 54 million working days are lost each year because of pain, strain and injuries to the back. Back strains are a common injury too. These can be caused by using poor techniques to move materials such as twisting and turning while lifting

Pre-start checklists are essential to ensure that employees and contractors assess all aspects of the equipment and workplace environment and greatly reduce accidents on work sites. Prior to operating the machine, the driver completes a visual assessment, check levels, wear, indicator lights, or signs of …

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

Tool Box Talks. Various types of Tool Box Talk documentation can be found down the left side of this page. A toolbox talk is a short safety talk, normally delivered on site (not in a training room) and on a specific subject matter.

Toolbox Safety Talk Personal Protective Equipment (PPE) Environmental Health & S afety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210

CASSA Compliant Automated Safety Systems Australia OHSE MANAGEMENT PLAN DATE: _15/01_/2011_ VERSION NO: _2__ 001 – Toolbox/pre-start talks

Toolbox Talks are intended to facilitate health and safety

Date Company Site Name After start Frequently used Site

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

Site briefing/toolbox meeting minutes Project information Who is running this meeting? Agenda items Health and safety issues This document is a companion document to the site inspection checklist. Site name Name Agenda items Theme of the week (topic for focus) Company Date Office location Date: Company Is this a site-specific or in-house meeting? Site Name After start Frequently used Site

Pre Use Safety Checks. Clean the outside of the machine. Make sure the harness is not damaged. Clean the air filter. Replace if necessary; Make sure the throttle trigger lock and the throttle function correctly from a safety point.

Tool Box Talk No 1 MANUAL HANDLING Page 1 of 1 Manual Handling Overview This talk will cover: considerations and good techniques for manual handling.

Our “toolbox talks packs” fact sheets are ready to go: short and succinct, covering over 100 topics in the electrotechnology industry. They are suitable for many different subjects and will help you get your safety message across to your workers.

Toolbox Safety Talk Personal Protective Equipment (PPE) Environmental Health & S afety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210

Tool Box Talk Plant Checks GAP Tool Box Talk: Plant Checks To provide guidance on: The precautions to be taken when working with Plant and Equipment Pre-use checks prior to work starting Regulations The Management of Health & Safety at Work Regulations 1999 Supply of Machinery (Safety) Regulations 2008 Provision and Use of Work Equipment Regulations 1998 Personal …

The person conducting the talk can use these questions to start a discussion that will make the information relevant to participating employees. Learn more. Links to additional resources are given for each Toolbox Talk. The links are provided to direct safety professionals and workers to publicly available information that can be used to learn more about the topic or modified to create

Toolbox talks / pre-start meetings Site Safe

Toolbox Safety Meetings/pre-Start Talks (Page 2 of 2) in pdf

The pre-start meeting is used as a tool to alert workers to these new training requirements and keep track of who has and has not completed it. Drug and Alcohol Screening While drug and alcohol screening routines are different on every site, the pre-start meeting is often one of the times at which random drug and alcohol testing is regularly conducted.

and Operational Works Decision Notices, including all pre-start requirements and any imposed conditions from Concurrence agencies. This document is in three parts and should be attached to any supporting documentation.

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

Free Toolbox Talks Download This package contains 70 toolbox talk documents covering a wide variety of health and safety issues in the workplace. All are in MS Word 97-2003 format and can be fully edited to include things like your company logo if required.

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

Manual Handling Tool Box talk Health & Safety Hub

PPE toolbox talk Cornell University

Tool Box Talk Issue: 1.0 Manual Handling Author: SHEQ Coordinator Approver: SHEQ Manager Approval Date: 19/03/12 Manual Handling Introduction In the UK, 54 million working days are lost each year because of pain, strain and injuries to the back. Back strains are a common injury too. These can be caused by using poor techniques to move materials such as twisting and turning while lifting

The term “Toolbox Talk” was originally used as a way to encourage building workers to have a regular documented safety meeting. The best time to do this was considered to be when they stood around the tool box in the morning before starting work, so the term Toolbox Talk was born.

Toolbox Safety Talk Personal Protective Equipment (PPE) Environmental Health & S afety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

Tool Box Talks. Various types of Tool Box Talk documentation can be found down the left side of this page. A toolbox talk is a short safety talk, normally delivered on site (not in a training room) and on a specific subject matter.

When ‘Hearts and Minds’ are not ‘Hearts and Minds’One of the profound findings of current neurophysiological and neuropsychological research is that the human person is an embodied mind, not a behaviourist computer on top of a body.Research by:Damasio – The Feeling of What Happens; Descartes ErrorVarela – The Embodied MindClaxton

Use the proper tool for the job Follow the manufacturer’s instructions If unsure about use, ask a supervisor or coworker for clarification

Inspect construction sites, restaurants inspections for food safety, conduct temperature checks, pre-flight checks, toolbox talks and more. It is the mobile forms inspection solution for all industries.

Toolbox or Pre-Start Talks are commonly used as a means of conducting and documenting the important information and training provided to workers. As the document is signed by the workers it provides proof of their attendance. If you require topics and information for discussion at your toolbox talks then you may benefi

Tool Box Talk Plant Checks GAP Tool Box Talk: Plant Checks To provide guidance on: The precautions to be taken when working with Plant and Equipment Pre-use checks prior to work starting Regulations The Management of Health & Safety at Work Regulations 1999 Supply of Machinery (Safety) Regulations 2008 Provision and Use of Work Equipment Regulations 1998 Personal …

084: Tools – Hand Tool Safety Why this is important A misapplied hand tool can easily result in injury. A worn or damaged tool can easily result in injury.

GAP Tool Box Talk Plant Checks

Equipment Pre Start Checklist Books Pertrain Pty Limited

CONTRACTORS PRE-START SAFETY CHECKLIST CONTRACTORS Pre-start SAFETY Checklist Published: February 2012 Version 1.0 Authorised by UWA …

out by the operator as soon as practicable at the start of the shift (or when the vehicle is put to work for the first time that shift). Recording Vehicle Daily Safety Checks Each vehicle must have its own Vehicle Daily Safety Check Book. The book should be kept in the vehicle cab so it can be filled in immediately after the daily checks have been done. Tarmac has two books for recording daily

Tool Box Talk Plant Checks GAP Tool Box Talk: Plant Checks To provide guidance on: The precautions to be taken when working with Plant and Equipment Pre-use checks prior to work starting Regulations The Management of Health & Safety at Work Regulations 1999 Supply of Machinery (Safety) Regulations 2008 Provision and Use of Work Equipment Regulations 1998 Personal …

Toolbox or Pre-Start Talks are commonly used as a means of conducting and documenting the important information and training provided to workers. As the document is signed by the workers it provides proof of their attendance. If you require topics and information for discussion at your toolbox talks then you may benefi

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

CONTRACTORS PRE-START SAFETY CHECKLIST

Manual Handling Tool Box talk Health & Safety Hub

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

Source: OHSE Subbypack, OSHE14 – Toolbox/ pre-start talks A10611150 Toolbox safety meetings/pre-start talks Ref: Version: All Toolbox safety meetings/pre-start talks undertaken on behalf of are recorded on this form

MR 003 Toolbox Pre-Start Talks For Advice On Your Workwear & Safety Order, Call Now

Pre-start checklists are essential to ensure that employees and contractors assess all aspects of the equipment and workplace environment and greatly reduce accidents on work sites. Prior to operating the machine, the driver completes a visual assessment, check levels, wear, indicator lights, or signs of …

Tool Box Talk No 1 MANUAL HANDLING Page 1 of 1 Manual Handling Overview This talk will cover: considerations and good techniques for manual handling.

CONTRACTORS PRE-START SAFETY CHECKLIST CONTRACTORS Pre-start SAFETY Checklist Published: February 2012 Version 1.0 Authorised by UWA …

out by the operator as soon as practicable at the start of the shift (or when the vehicle is put to work for the first time that shift). Recording Vehicle Daily Safety Checks Each vehicle must have its own Vehicle Daily Safety Check Book. The book should be kept in the vehicle cab so it can be filled in immediately after the daily checks have been done. Tarmac has two books for recording daily

Toolbox talks are a way to ensure all workers are participating in safety activities, and have an opportunity to discuss hazards/controls, incidents and accidents.

Toolbox or Pre-Start Talks are commonly used as a means of conducting and documenting the important information and training provided to workers. As the document is signed by the workers it provides proof of their attendance. If you require topics and information for discussion at your toolbox talks then you may benefi

Download these safety talks, print them up, and use them in your pre-shift, workplace, employee safety meetings (aka tool box talks or tailgate talks). You also might want to use them in – monthly department safety meetings, and your new hire safety orientation training program.

The term “Toolbox Talk” was originally used as a way to encourage building workers to have a regular documented safety meeting. The best time to do this was considered to be when they stood around the tool box in the morning before starting work, so the term Toolbox Talk was born.

All Toolbox / Pre-start Talks undertaken on behalf of [Insert Company Name] are recorded on this form and signed by participants. All corrective actions noted on this form are implemented and signed by the nominated person.

PPE toolbox talk Cornell University

Pre-start meeting tips Safety Action

Daily Toolbox Meeting Form End-of Day Review: Were there any Incidents, Injuries or First-Aid Reports for the day?: Yes No Describe:

Site briefing/toolbox meeting minutes Project information Who is running this meeting? Agenda items Health and safety issues This document is a companion document to the site inspection checklist. Site name Name Agenda items Theme of the week (topic for focus) Company Date Office location Date: Company Is this a site-specific or in-house meeting? Site Name After start Frequently used Site

Health and safety talks are easier to start when you have something prepared, so get some notes together on a relevant subject, or use one of our pre-prepared toolbox talks. This article was written by Emma at HASpod .

CONTRACTORS PRE-START SAFETY CHECKLIST CONTRACTORS Pre-start SAFETY Checklist Published: February 2012 Version 1.0 Authorised by UWA …

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

and Operational Works Decision Notices, including all pre-start requirements and any imposed conditions from Concurrence agencies. This document is in three parts and should be attached to any supporting documentation.

Toolbox Talk Machine Safety – Before Operations Pre-Start Procedures Read and understand the Operation and Maintenance Manual Always perform a pre-shift walk around inspection

With SiteDocs you can upload pre-written safety talks to your account and have your workers instantly access them on their iphone/android or tablet. Once they have read the toolbox talk, workers will be able to select their name and sign the form right on the device. Rest assured, every worker that is part of the safety meeting will be able to sign off on the same form.

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

Toolbox Safety Meetings/pre-Start Talks (Page 2 of 2) in pdf

Points raised/comments Corrective action Action by Action

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

When ‘Hearts and Minds’ are not ‘Hearts and Minds’One of the profound findings of current neurophysiological and neuropsychological research is that the human person is an embodied mind, not a behaviourist computer on top of a body.Research by:Damasio – The Feeling of What Happens; Descartes ErrorVarela – The Embodied MindClaxton

With SiteDocs you can upload pre-written safety talks to your account and have your workers instantly access them on their iphone/android or tablet. Once they have read the toolbox talk, workers will be able to select their name and sign the form right on the device. Rest assured, every worker that is part of the safety meeting will be able to sign off on the same form.

084: Tools – Hand Tool Safety Why this is important A misapplied hand tool can easily result in injury. A worn or damaged tool can easily result in injury.

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

Site briefing/toolbox meeting minutes Project information Who is running this meeting? Agenda items Health and safety issues This document is a companion document to the site inspection checklist. Site name Name Agenda items Theme of the week (topic for focus) Company Date Office location Date: Company Is this a site-specific or in-house meeting? Site Name After start Frequently used Site

Pre Use Safety Checks. Clean the outside of the machine. Make sure the harness is not damaged. Clean the air filter. Replace if necessary; Make sure the throttle trigger lock and the throttle function correctly from a safety point.

Toolbox or Pre-Start Talks are commonly used as a means of conducting and documenting the important information and training provided to workers. As the document is signed by the workers it provides proof of their attendance. If you require topics and information for discussion at your toolbox talks then you may benefi

Toolbox Safety Talks Rockwood

GAP Tool Box Talk Plant Checks

Pre-start checklists are essential to ensure that employees and contractors assess all aspects of the equipment and workplace environment and greatly reduce accidents on work sites. Prior to operating the machine, the driver completes a visual assessment, check levels, wear, indicator lights, or signs of …

Toolbox Safety Talk Hand and Power Tools Environmental Health & Safety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210 Ithaca, NY 14850

out by the operator as soon as practicable at the start of the shift (or when the vehicle is put to work for the first time that shift). Recording Vehicle Daily Safety Checks Each vehicle must have its own Vehicle Daily Safety Check Book. The book should be kept in the vehicle cab so it can be filled in immediately after the daily checks have been done. Tarmac has two books for recording daily

Source: OHSE Subbypack, OSHE14 – Toolbox/ pre-start talks A10611150 Toolbox safety meetings/pre-start talks Ref: Version: All Toolbox safety meetings/pre-start talks undertaken on behalf of are recorded on this form

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

Health and safety talks are easier to start when you have something prepared, so get some notes together on a relevant subject, or use one of our pre-prepared toolbox talks. This article was written by Emma at HASpod .

Tool Box Talk Issue: 1.0 Manual Handling Author: SHEQ Coordinator Approver: SHEQ Manager Approval Date: 19/03/12 Manual Handling Introduction In the UK, 54 million working days are lost each year because of pain, strain and injuries to the back. Back strains are a common injury too. These can be caused by using poor techniques to move materials such as twisting and turning while lifting

084: Tools – Hand Tool Safety Why this is important A misapplied hand tool can easily result in injury. A worn or damaged tool can easily result in injury.

When ‘Hearts and Minds’ are not ‘Hearts and Minds’One of the profound findings of current neurophysiological and neuropsychological research is that the human person is an embodied mind, not a behaviourist computer on top of a body.Research by:Damasio – The Feeling of What Happens; Descartes ErrorVarela – The Embodied MindClaxton

Download these safety talks, print them up, and use them in your pre-shift, workplace, employee safety meetings (aka tool box talks or tailgate talks). You also might want to use them in – monthly department safety meetings, and your new hire safety orientation training program.

A-Z of Safety Toolbox Topics Toolbox Talks R NECA

Pre Use Safety Checks Inland Waterways Association

The pre-start meeting is used as a tool to alert workers to these new training requirements and keep track of who has and has not completed it. Drug and Alcohol Screening While drug and alcohol screening routines are different on every site, the pre-start meeting is often one of the times at which random drug and alcohol testing is regularly conducted.

Tool Box Talk No 1 MANUAL HANDLING Page 1 of 1 Manual Handling Overview This talk will cover: considerations and good techniques for manual handling.

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

All Toolbox / Pre-start Talks undertaken on behalf of [Insert Company Name] are recorded on this form and signed by participants. All corrective actions noted on this form are implemented and signed by the nominated person.

Pre Use Safety Checks. Clean the outside of the machine. Make sure the harness is not damaged. Clean the air filter. Replace if necessary; Make sure the throttle trigger lock and the throttle function correctly from a safety point.

Tool Box Talk Scenarios 2 and 6 Working on Fixed Plant/Conveyors Introduction Cleaning or adjusting machinery while it is running and the unexpected start up of equipment has caused

52 Responses

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

70 Workplace Safety Talks « Safety Awakenings

How To Start A Safety Talk HASpod

Source: OHSE Subbypack, OSHE14 – Toolbox/ pre-start talks A10611150 Toolbox safety meetings/pre-start talks Ref: Version: All Toolbox safety meetings/pre-start talks undertaken on behalf of are recorded on this form

A-Z of Safety Toolbox Topics Toolbox Talks T NECA

Toolbox Safety Talks Rockwood

Tool Box Talk No 1 MANUAL HANDLING Page 1 of 1 Manual Handling Overview This talk will cover: considerations and good techniques for manual handling.

Toolbox Talk Machine Safety Before Operations Pre-Start

70 Workplace Safety Talks « Safety Awakenings

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

Toolbox Talk #10 HAND & POWER TOOLS

Manual Handling Tool Box talk Health & Safety Hub

CONTRACTORS PRE-START SAFETY CHECKLIST

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

Free Toolbox Talks Seguro H&S Management

Toolbox Talk Machine Safety – Before Operations Pre-Start Procedures Read and understand the Operation and Maintenance Manual Always perform a pre-shift walk around inspection

Pre-start meeting tips Safety Action

VEHICLE DAILY SAFETY CHECKS safequarry.com

084: Tools – Hand Tool Safety Why this is important A misapplied hand tool can easily result in injury. A worn or damaged tool can easily result in injury.

Points raised/comments Corrective action Action by Action

70 Workplace Safety Talks « Safety Awakenings

Download these safety talks, print them up, and use them in your pre-shift, workplace, employee safety meetings (aka tool box talks or tailgate talks). You also might want to use them in – monthly department safety meetings, and your new hire safety orientation training program.

Toolbox or Pre-Start Talks Form – Occupational Safety

Tool Box Talk Issue: 1.0 Manual Handling Author: SHEQ Coordinator Approver: SHEQ Manager Approval Date: 19/03/12 Manual Handling Introduction In the UK, 54 million working days are lost each year because of pain, strain and injuries to the back. Back strains are a common injury too. These can be caused by using poor techniques to move materials such as twisting and turning while lifting

Pre-start meeting tips Safety Action

Points raised/comments Corrective action Action by Action

Pre-shift inspections provide an opportunity to observe and report maintenance and safety concerns for any equipment. Be Prepared – Read and know the operator’s manual for specific equipment. – Understand the importance of completing pre-shift inspection. – Stress to fellow employees the importance of pre-shift inspection. Inspect Carefully – Inspect the ENTIRE piece of equipment

Tool box talk templates for Toolbox Procedures Toolbox

Pre-start checklists are essential to ensure that employees and contractors assess all aspects of the equipment and workplace environment and greatly reduce accidents on work sites. Prior to operating the machine, the driver completes a visual assessment, check levels, wear, indicator lights, or signs of …

CONTRACTORS PRE-START SAFETY CHECKLIST

Date Company Site Name After start Frequently used Site

Tool Box Talk Scenarios 2 and 6 Working on Fixed Plant/Conveyors Introduction Cleaning or adjusting machinery while it is running and the unexpected start up of equipment has caused

A-Z of Safety Toolbox Topics Toolbox Talks R NECA

70 Workplace Safety Talks « Safety Awakenings

With SiteDocs you can upload pre-written safety talks to your account and have your workers instantly access them on their iphone/android or tablet. Once they have read the toolbox talk, workers will be able to select their name and sign the form right on the device. Rest assured, every worker that is part of the safety meeting will be able to sign off on the same form.

Tool box talk templates for Toolbox Procedures Toolbox

Toolbox Talking Points Barton Malow Company

Pre Use Safety Checks Inland Waterways Association

All Toolbox / Pre-start Talks undertaken on behalf of [Insert Company Name] are recorded on this form and signed by participants. All corrective actions noted on this form are implemented and signed by the nominated person.

PRE-START MEETING PROCESS cairns.qld.gov.au

084: Tools – Hand Tool Safety Why this is important A misapplied hand tool can easily result in injury. A worn or damaged tool can easily result in injury.

Toolbox Safety Meetings/pre-Start Talks printable pdf download

Date Company Site Name After start Frequently used Site

ECSS Manual Handling No 1 ecsafetysolutions.com

88 Toolbox Safety Talks Heavy Equipment Start-Up Rockwood Casualty Insurance Company (Rockwood) may provide safety management services to its insureds in order to

Toolbox Pre-Start Talks NECA Safety Specialists

Toolbox Talk Machine Safety Before Operations Pre-Start

View, download and print Toolbox Safety Meetings/pre-start Talks pdf template or form online. 6 Safety Meeting Templates are collected for any of your needs.

TOOLBOX PRE-START TALKS businesssavvy.com.au

084 Tools – Hand Tool Safety NECA

CASSA Compliant Automated Safety Systems Australia OHSE MANAGEMENT PLAN DATE: _15/01_/2011_ VERSION NO: _2__ 001 – Toolbox/pre-start talks

Pre-Start Checklists Lockbox Safety Documentation

How To Start A Safety Talk HASpod

The term “Toolbox Talk” was originally used as a way to encourage building workers to have a regular documented safety meeting. The best time to do this was considered to be when they stood around the tool box in the morning before starting work, so the term Toolbox Talk was born.

Toolbox Pre-Start Talks NECA Safety Specialists

Keep mirrors clean and tires at proper WorkSAFE Tips

and Operational Works Decision Notices, including all pre-start requirements and any imposed conditions from Concurrence agencies. This document is in three parts and should be attached to any supporting documentation.

084 Tools – Hand Tool Safety NECA

Pre-start checklists are essential to ensure that employees and contractors assess all aspects of the equipment and workplace environment and greatly reduce accidents on work sites. Prior to operating the machine, the driver completes a visual assessment, check levels, wear, indicator lights, or signs of …

CONTRACTORS PRE-START SAFETY CHECKLIST

Free Toolbox Talks Seguro H&S Management

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

A-Z of Safety Toolbox Topics Toolbox Talks T NECA

Toolbox Safety Meetings/pre-Start Talks printable pdf download

VEHICLE DAILY SAFETY CHECKS safequarry.com

Site briefing/toolbox meeting minutes Project information Who is running this meeting? Agenda items Health and safety issues This document is a companion document to the site inspection checklist. Site name Name Agenda items Theme of the week (topic for focus) Company Date Office location Date: Company Is this a site-specific or in-house meeting? Site Name After start Frequently used Site

Pre Use Safety Checks Inland Waterways Association

Toolbox Safety Talks Rockwood

The pre-start meeting is used as a tool to alert workers to these new training requirements and keep track of who has and has not completed it. Drug and Alcohol Screening While drug and alcohol screening routines are different on every site, the pre-start meeting is often one of the times at which random drug and alcohol testing is regularly conducted.

Toolbox Talk #10 HAND & POWER TOOLS

Toolbox Safety Meetings/pre-Start Talks (Page 2 of 2) in pdf

Use the proper tool for the job Follow the manufacturer’s instructions If unsure about use, ask a supervisor or coworker for clarification

Free Toolbox Talks Seguro H&S Management

Tool box talk templates for Toolbox Procedures Toolbox

TOOL BOX TALK Vehicle Safety Inspections Introduction: The condition of your vehicle is a safety factor that you, the driver, can control. You decide when the maintenance is done and at what intervals. But what are the risks when vehicle maintenance is neglected? One risk is the inability to maintain control? Another risk is a break down on the side of the highway? Budget money for regular

Toolbox Safety Meetings/pre-Start Talks printable pdf download

VEHICLE DAILY SAFETY CHECKS safequarry.com

Toolbox talks / pre-start meetings Site Safe

Site briefing/toolbox meeting minutes Project information Who is running this meeting? Agenda items Health and safety issues This document is a companion document to the site inspection checklist. Site name Name Agenda items Theme of the week (topic for focus) Company Date Office location Date: Company Is this a site-specific or in-house meeting? Site Name After start Frequently used Site

001 Toolbox/pre-start talks – cassaaustralia.com.au

PPE toolbox talk Cornell University

Toolbox Talking Points Barton Malow Company

Pre Use Safety Checks. Clean the outside of the machine. Make sure the harness is not damaged. Clean the air filter. Replace if necessary; Make sure the throttle trigger lock and the throttle function correctly from a safety point.

GAP Tool Box Talk Plant Checks

CONTRACTORS PRE-START SAFETY CHECKLIST

PPE toolbox talk Cornell University

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

Pre-start meeting tips Safety Action

Toolbox Safety Meetings/pre-Start Talks printable pdf download

Toolbox talks / pre-start meetings Site Safe

Inspect construction sites, restaurants inspections for food safety, conduct temperature checks, pre-flight checks, toolbox talks and more. It is the mobile forms inspection solution for all industries.

The Pre-Start Meeting Mining Oil and Gas Careers Guide

GAP Tool Box Talk Plant Checks

and Operational Works Decision Notices, including all pre-start requirements and any imposed conditions from Concurrence agencies. This document is in three parts and should be attached to any supporting documentation.

70 Workplace Safety Talks « Safety Awakenings

Free Toolbox Talks Download This package contains 70 toolbox talk documents covering a wide variety of health and safety issues in the workplace. All are in MS Word 97-2003 format and can be fully edited to include things like your company logo if required.

A-Z of Safety Toolbox Topics Toolbox Talks T NECA

CONTRACTORS PRE-START SAFETY CHECKLIST

Do not attempt to start equipment/machines that are locked out or tagged out. Do not attempt to remove or tamper with locks or tags for any reason. Only use tools and machines that you are trained and authorized to use.

Toolbox talks / pre-start meetings Site Safe

Keep mirrors clean and tires at proper WorkSAFE Tips

Tool Box Talks. Various types of Tool Box Talk documentation can be found down the left side of this page. A toolbox talk is a short safety talk, normally delivered on site (not in a training room) and on a specific subject matter.

Equipment Pre Start Checklist Books Pertrain Pty Limited

Toolbox or Pre-Start Talks Form – Occupational Safety

Pre Use Safety Checks. Clean the outside of the machine. Make sure the harness is not damaged. Clean the air filter. Replace if necessary; Make sure the throttle trigger lock and the throttle function correctly from a safety point.

Pre-Start Checklists Lockbox Safety Documentation

PRE-START MEETING PROCESS cairns.qld.gov.au

Toolbox/Pre-start talks Toolbox/Pre-start talks_0313 Contractor name Contractor ID Project name Duration Toolbox/Pre-start talks are recorded on this form and signed by participants.

Toolbox Pre-Start Talks NECA Safety Specialists

TOOL BOX TALKS A YEAR’S WORTH OF WEEKLY SAFETY

Toolbox Talks CPWR

Our “toolbox talks packs” fact sheets are ready to go: short and succinct, covering over 100 topics in the electrotechnology industry. They are suitable for many different subjects and will help you get your safety message across to your workers.

Toolbox talks / pre-start meetings Site Safe

Toolbox Safety Meetings/pre-Start Talks (Page 2 of 2) in pdf

Toolbox or Pre-Start Talks Form – Occupational Safety

Toolbox Safety Talk Hand and Power Tools Environmental Health & Safety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210 Ithaca, NY 14850

Toolbox Safety Meetings/pre-Start Talks printable pdf download

A-Z of Safety Toolbox Topics Toolbox Talks T NECA

TOOLBOX PRE-START TALKS businesssavvy.com.au

Free Toolbox Talks Download This package contains 70 toolbox talk documents covering a wide variety of health and safety issues in the workplace. All are in MS Word 97-2003 format and can be fully edited to include things like your company logo if required.

Toolbox Talk Machine Safety Before Operations Pre-Start

Toolbox talks / pre-start meetings Site Safe

Tool Box Talk Plant Checks GAP Tool Box Talk: Plant Checks To provide guidance on: The precautions to be taken when working with Plant and Equipment Pre-use checks prior to work starting Regulations The Management of Health & Safety at Work Regulations 1999 Supply of Machinery (Safety) Regulations 2008 Provision and Use of Work Equipment Regulations 1998 Personal …

PRE-START MEETING PROCESS cairns.qld.gov.au

Pre-start meeting tips Safety Action

Daily Toolbox Meeting Form End-of Day Review: Were there any Incidents, Injuries or First-Aid Reports for the day?: Yes No Describe:

Pre-start meeting tips Safety Action

Points raised/comments Corrective action Action by Action

VEHICLE DAILY SAFETY CHECKS safequarry.com

These are also referred to as; toolbox talks, (daily) site inductions, or line-side briefings. It doesn’t matter what you call them they are generally a good idea.

A-Z of Safety Toolbox Topics Toolbox Talks R NECA

CONTRACTORS PRE-START SAFETY CHECKLIST

Pre-Start Checklists Lockbox Safety Documentation

(Charlas Informativas de Seguridad Ocupacional) CPWR maintains a large collection of toolbox talks and has worked closely with NIOSH to ensure that this series incorporates effective elements like case studies, discussion questions, and site-specific actions.

PPE toolbox talk Cornell University

Toolbox/Pre-start talks Toolbox/Pre-start talks_0313 Contractor name Contractor ID Project name Duration Toolbox/Pre-start talks are recorded on this form and signed by participants.

Date Company Site Name After start Frequently used Site

Toolbox Safety Talks Rockwood

Toolbox or Pre-Start Talks Form – Occupational Safety

Toolbox Safety Talk Personal Protective Equipment (PPE) Environmental Health & S afety Facilities Safety & Health Section 395 Pine Tree Rd. Suite 210

Toolbox talks / pre-start meetings Site Safe

Pre-start meeting tips Safety Action

View, download and print Toolbox Safety Meetings/pre-start Talks pdf template or form online. 6 Safety Meeting Templates are collected for any of your needs.

Tool box talk templates for Toolbox Procedures Toolbox

CONTRACTORS PRE-START SAFETY CHECKLIST

and Operational Works Decision Notices, including all pre-start requirements and any imposed conditions from Concurrence agencies. This document is in three parts and should be attached to any supporting documentation.

Equipment Pre Start Checklist Books Pertrain Pty Limited

All Toolbox / Pre-start Talks undertaken on behalf of [Insert Company Name] are recorded on this form and signed by participants. All corrective actions noted on this form are implemented and signed by the nominated person.

Toolbox or Pre-Start Talks Form – Occupational Safety

Daily Toolbox Meeting Form End-of Day Review: Were there any Incidents, Injuries or First-Aid Reports for the day?: Yes No Describe:

A-Z of Safety Toolbox Topics Toolbox Talks T NECA

PRE-START MEETING PROCESS cairns.qld.gov.au

TOOLBOX PRE-START TALKS businesssavvy.com.au

Tool box talks, safety moments and pre-start meetings have become a very effective way of maintaining safety awareness and bringing attention to any current or emerging hazards and risks.

CONTRACTORS PRE-START SAFETY CHECKLIST

Toolbox Talks are intended to facilitate health and safety

084 Tools – Hand Tool Safety NECA

Equipment Pre Start Checklist. A Equipment Pre Start Checklist helps you to assess the serviceability of your equipment before you use it. They will assist to uncover potential hazards or flaws due to misuse, wear and tear or poor maintenance.

TOOLBOX PRE-START TALKS businesssavvy.com.au

SafetyRisk.net Humanising Safety and Embracing Real Risk

TOOL BOX TALK Vehicle Safety Inspections Introduction: The condition of your vehicle is a safety factor that you, the driver, can control. You decide when the maintenance is done and at what intervals. But what are the risks when vehicle maintenance is neglected? One risk is the inability to maintain control? Another risk is a break down on the side of the highway? Budget money for regular

SafetyRisk.net Humanising Safety and Embracing Real Risk

TOOLBOX PRE-START TALKS businesssavvy.com.au

Toolbox Talk #10 HAND & POWER TOOLS

Comments are closed.